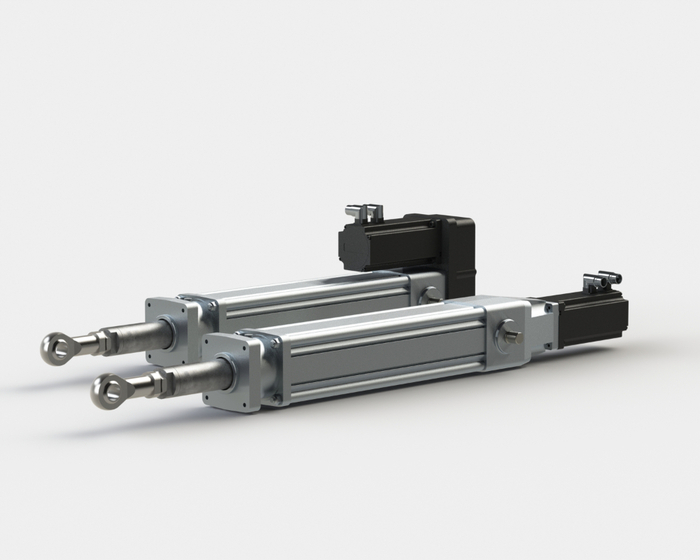

Servo lift cylinder

Servo electric cylinders are equipped with a ball screw for maximum energy efficiency. With this spindle, the rotary movement of the drive motor is converted into a linear movement with the lowest possible power losses.

The rotary motion of the drive motors is transmitted to the ball screw spindle via a direct attachment (in-line) or a parallel attachment. In conjunction with servo motors, highly accurate positioning <0.05 mm is possible. Likewise, the lifting force can be monitored and regulated via the engine torque.

In an increasing number of applications, the high demands of pneumatic cylinders can no longer be achieved. In these cases, the servo electric cylinders are an excellent alternative for realising the desired parameters such as lifting speed, lifting force, positioning accuracy, path and force monitoring etc.

Advantages:

- Minimal maintenance costs

- Compact construction

- Uniform lifting speed with and without load

- Exact positioning

- Safe holding of the load at a standstill (with brake motor)

- High axial stiffness

Modular system:

- Motor mounting parallel, coaxial (in-line)

- Available with servo motor or motor mounting according to customer requirements

- 7 standard sizes available (SA0-SA6)

- Ball screws from ø12 mm to ø40 mm

- Load capacity up to 46 kN

- Linear lifting speed up to 1,500 mm/s

Sizes of the SA series:

| Size | SA0 | SA1 | SA2 | SA3 | SA4 | SA5 | SA6 |

| Fmax. [N] | 5,500 | 5,500 | 6,400 | 8,600 | 12,000 | 37,000 | 46,000 |

| vmax. [mm/s] / at spindle pitch [mm] |

625 /5 |

536 /5 |

470 /5 |

375 / 5 |

300 /5 |

234/ 5 |

187 /5 |

| Spindle diameter x pitch [mm] |

ø12x5 |

ø14x5 |

ø16x5 |

ø20x5 |

ø25x5 |

ø32x5 |

ø40x5 |