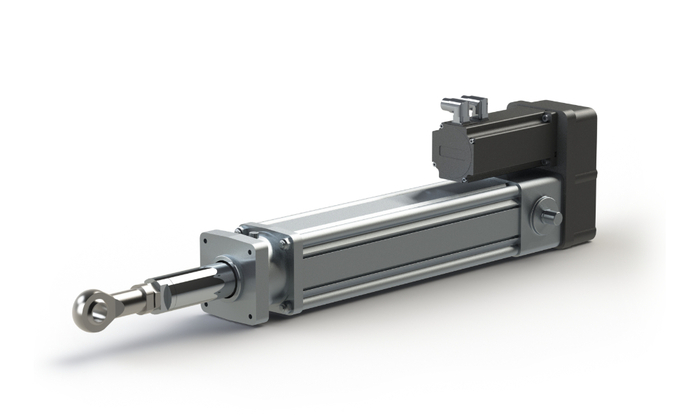

Electromechanical lifting cylinders

living article - read the following article about the design and calculation of electromechanical linear drives. We would like to provide you with some information that is necessary for the design and dimensioning of electric lifting cylinders. We will gradually present the basis for the calculation of the interpretation in a white paper and continuously expand it.

Calculation basis - drive design

For the optimal design of an electromechanical lifting cylinder, the data of the application must first be determined. This calculates the individual components of the entire drive train, consisting of the mechanics and the electric drive. When selecting a suitable lifting cylinder, both the maximum forces and speeds as well as the equivalent values relevant for the required service life must be taken into account. The limit values, specified by the manufacturers in the product catalogues, must not be exceeded. For applications with a low lifting speed and short duty cycle, in which the service life and energy consumption play a minor role, lifting cylinders with trapezoidal threaded spindles are often also used for economic reasons. In all other cases, ball screws are usually used with roller screws being used for higher loads. The design steps described below apply to electromechanical lifting cylinders with ball screw

Specification of application data

- Application description

- Mounting conditions

- Assembly position

- Axial forces (tension, pressure)

- masses to be accelerated

- Load profile

- Stroke length

- Positioning time

- Maximum lifting speed

- Number of load cycles per hour

- Required service life

What do we do for you?

Finding a solution that is optimally tailored to my needs is often very difficult. Most of the time, companies are pushing their customers to solutions that may not be optimal for your needs. ATP offers you a manufacturer-independent design of your drive and thus also the optimal solution for your application.

What we offer:

- Analysis of requirements

- Specification of the design data

- Optimal design and dimensioning of the components

- A ready-to-install solution for your needs