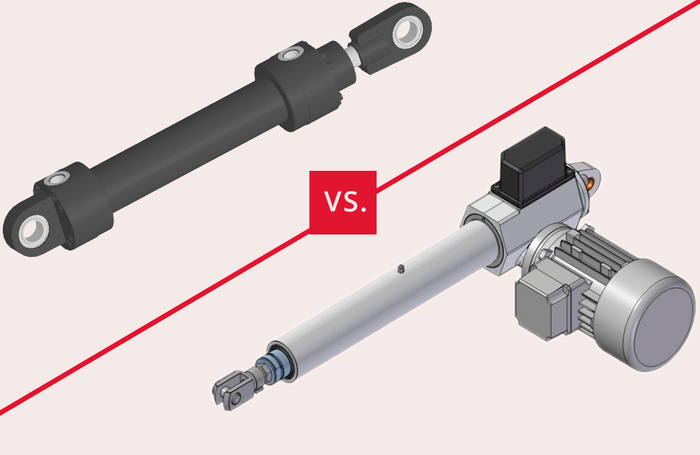

A comprehensive comparison between electric cylinder and hydraulic cylinder

The drive with which the best results are achieved varies depending on the application and industry. Therefore, the decision for an electric or a hydraulic cylinder depends above all on a precise analysis of the operating conditions.

Once all the necessary data of the application for dimensioning is available, the search for the ideal solution can begin.

Particularly important for this are the description of the load collective of the lifting movement and the number of load cycles in a certain period of time. The required service life also depends on whether the drive runs, for example, 3 times per minute, 10 times per day or with a duty cycle of 80%.

Knowing the area of application and use as precisely as possible is important both for new construction design and for the conversion in the event of a technology change.

The advantages and disadvantages of electric and hydraulic cylinders at a glance

Which cylinder is used does not only depend on the field of application and use, but also on the criteria summarized in the following table:

|

|

Electric cylinder |

Hydraulic cylinder |

|---|---|---|

|

Installation |

The electrical installation is simple and cost-effective. A further saving results from the omission of the hydraulic unit. |

Hydraulics requires pipes, hoses, filters and pumps. Both the material and the installation costs are higher here. |

|

Reliability, maintenance and environment |

The electric cylinder has a higher energy efficiency and a better efficiency. There is little maintenance required.

|

On the one hand, the use of hydraulic oil creates more maintenance costs, on the other hand, oil loss creates a danger to the environment. Pressure losses due to leaks lead to operational malfunctions. |

|

Service life |

The service life can be calculated accurately with the load spectrum with the movement cycle and the duty cycle. |

The service life depends, among other things, on the seals and the operating pressure. Since an exact calculation of the service life is not possible, empirical values are used. |

|

Safety and positioning accuracy |

Heavy loads are held securely even in the event of a power failure due to holding brakes. |

Through the use of special clamping systems, a high degree of safety can be achieved. The accuracy can be significantly improved by installing expensive sensors. |

|

Noise |

Low |

High |

|

Cost structure |

Acquisition high; operation and maintenance low |

Acquisition high; operation and maintenance high |

Electric cylinders are the better choice here!

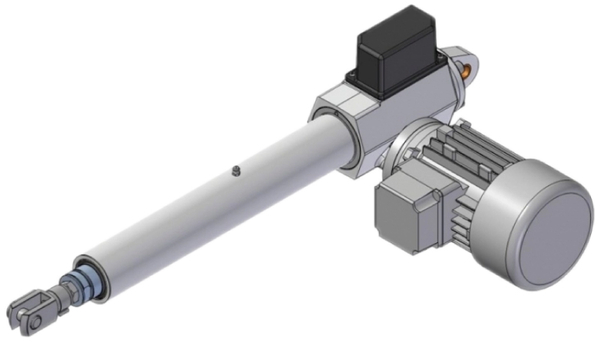

The electric cylinder is always the better choice when a decentralised drive, a particularly clean working environment and precise work are required.

Classical areas of application or industries are, for example:

- Conveyor technology (cranes, cable cars)

- Positioning Systems

- Lifting systems

- Metalworking

- Stage equipment

- Energie and environmental engineering

- Work platforms

Here, it makes sense to use hydraulic cylinders!

The use of hydraulic cylinders has been common in almost all industries, especially in the past. Due to its numerous advantages, the electric cylinder has gained market share in many applications, but there are some areas of application in which hydraulic cylinders can still not be replaced:

- Use in potentially explosive areas

- Mobile applications such as agricultural machinery or construction machinery

- Applications with very large forces

What should be considered, when switching from hydraulic cylinders to electric cylinders!

In the case of a changeover, exact planning and dimensioning is necessary, since an exchange is not possible 1:1. Above all, it is important to make ideal use of the available installation space and to plan not only the electromechanical components, but also the connection construction. In order to ensure a smooth retrofitting phase, the support of experts has proven itself. ATP can help here, as the well-trained technicians have many years of expertise for applications in a wide variety of industries and contribute their experience both in new construction, in a conversion or a technology change.

Efficient drive design

We ensure the correct selection and dimensioning of the electric lifting cylinders for your individual requirements.